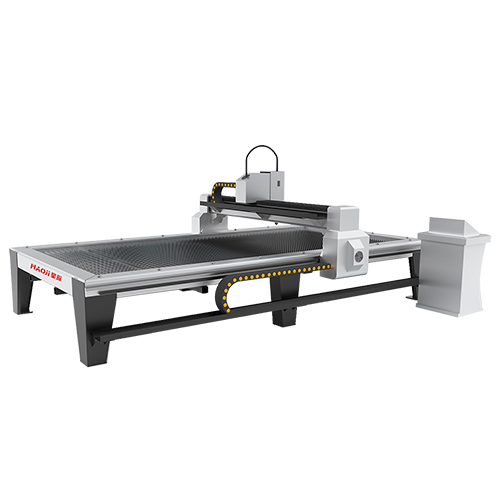

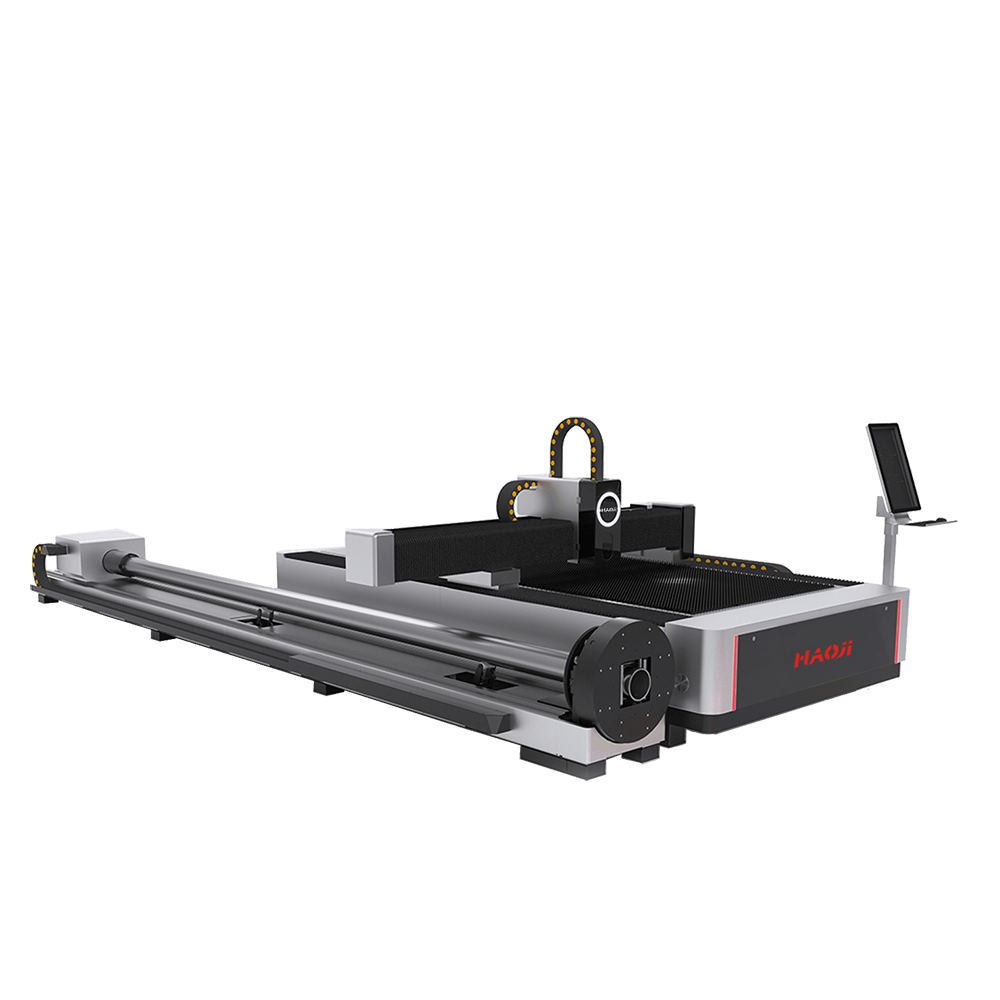

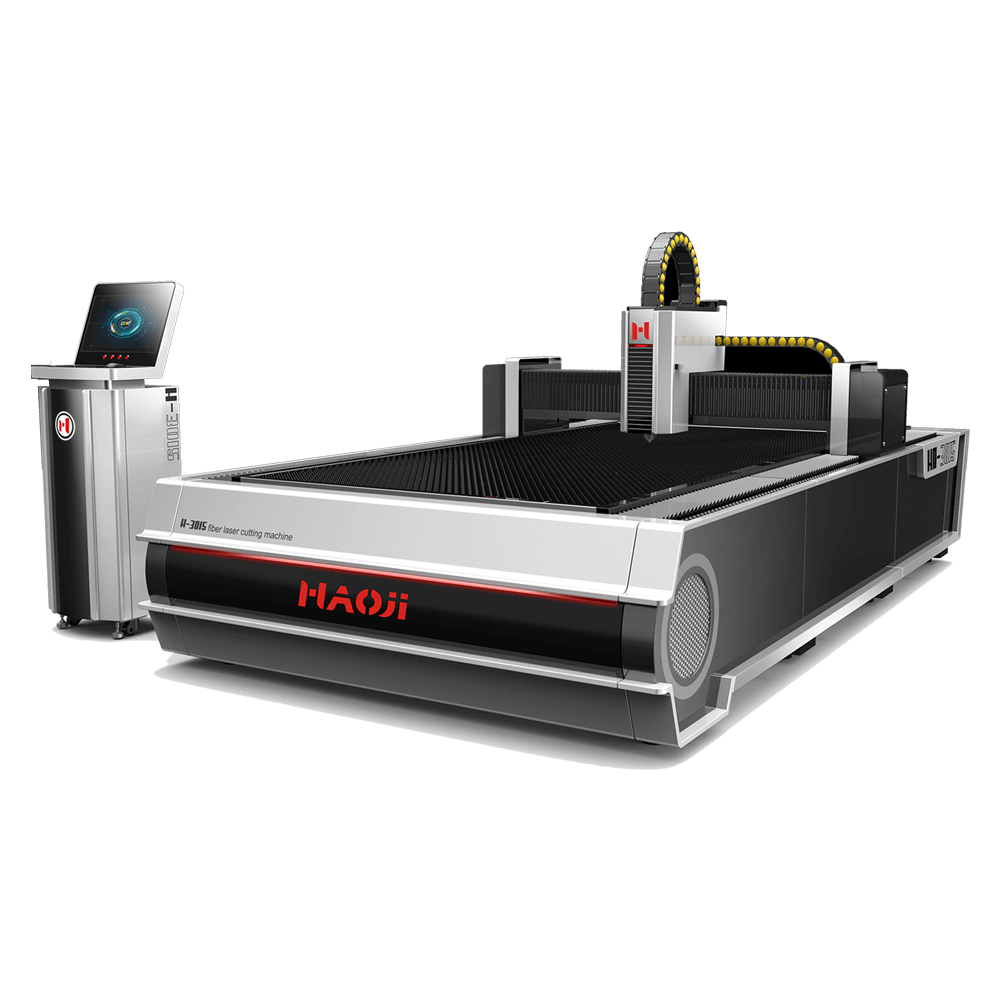

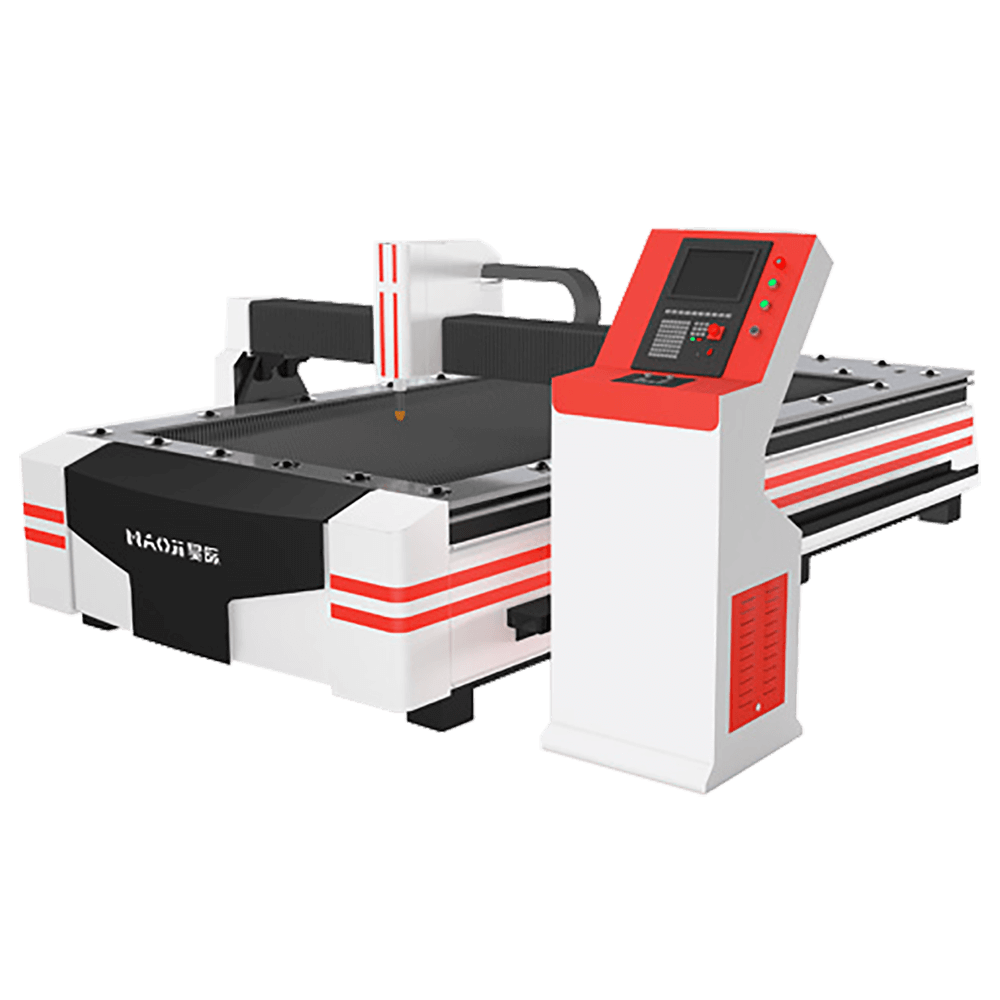

Laser power

1000~20000WMax. moving speed

140m/minRepeat positioning accuracy

0.02mmBlessing diameter

/

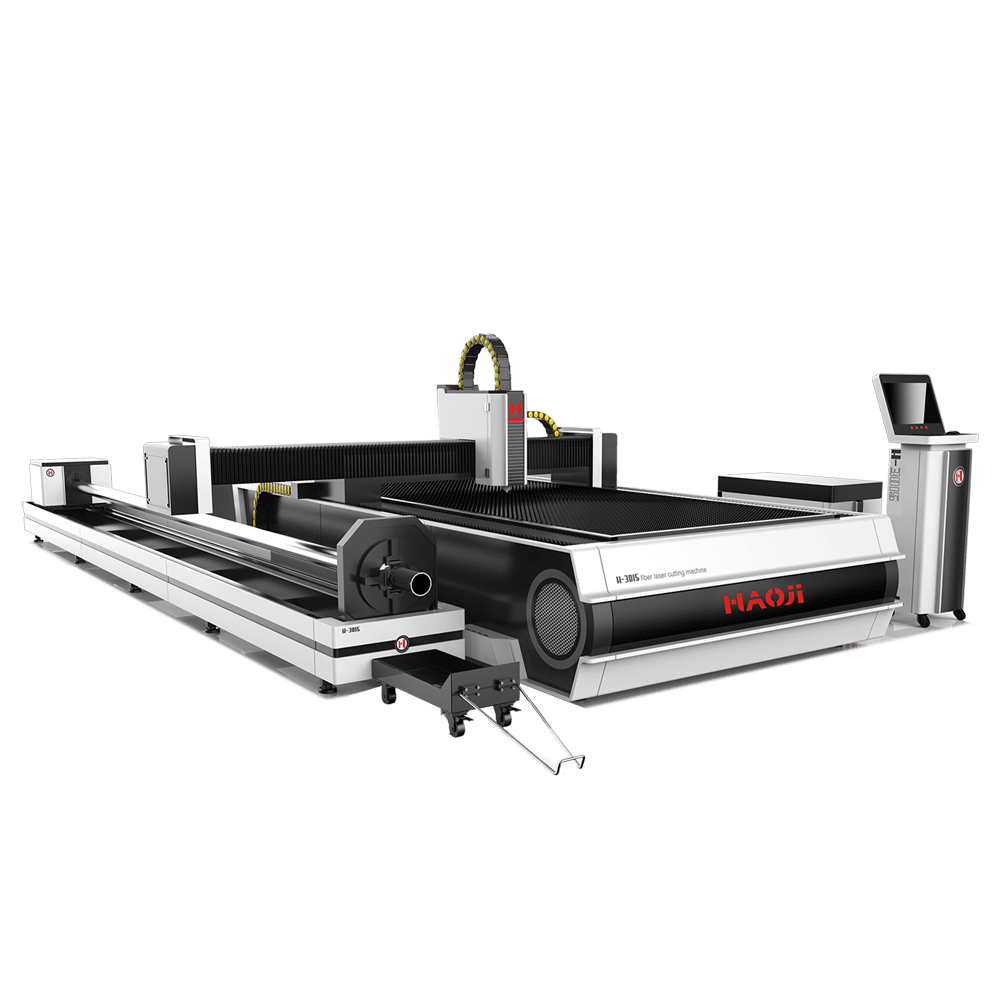

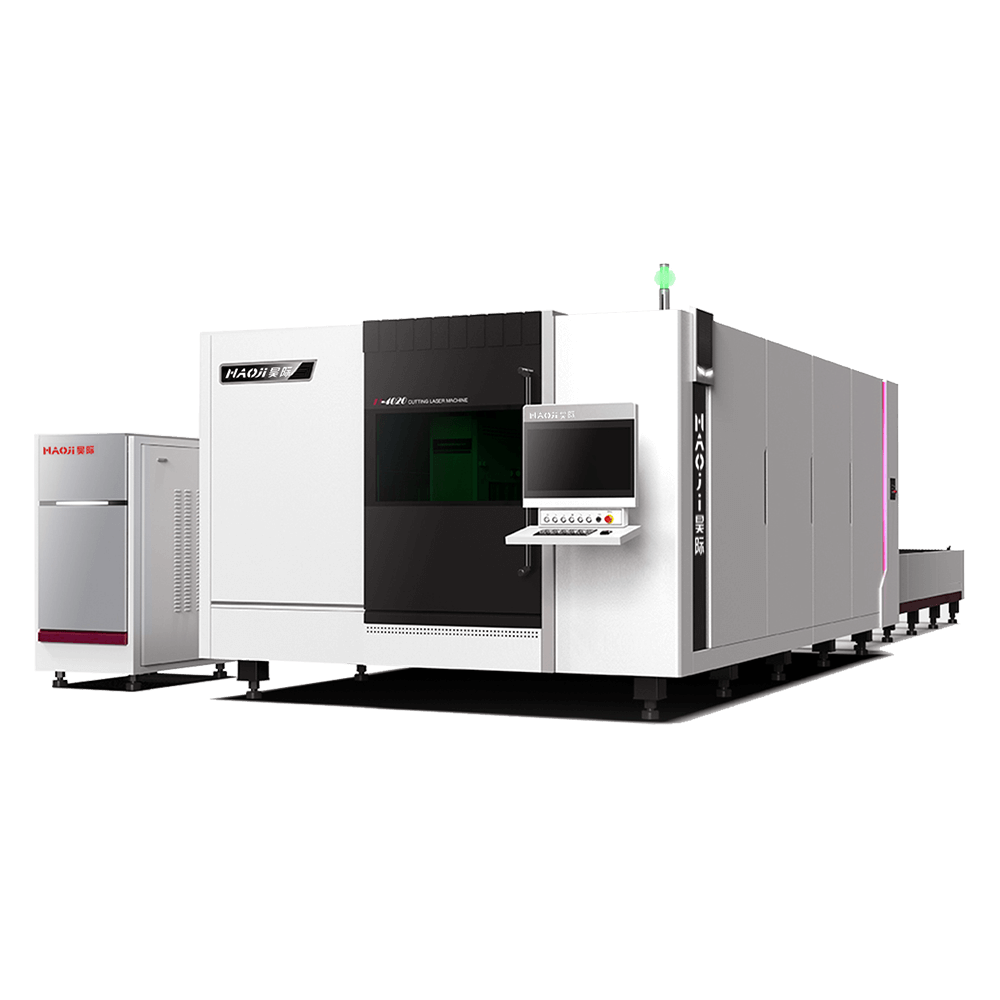

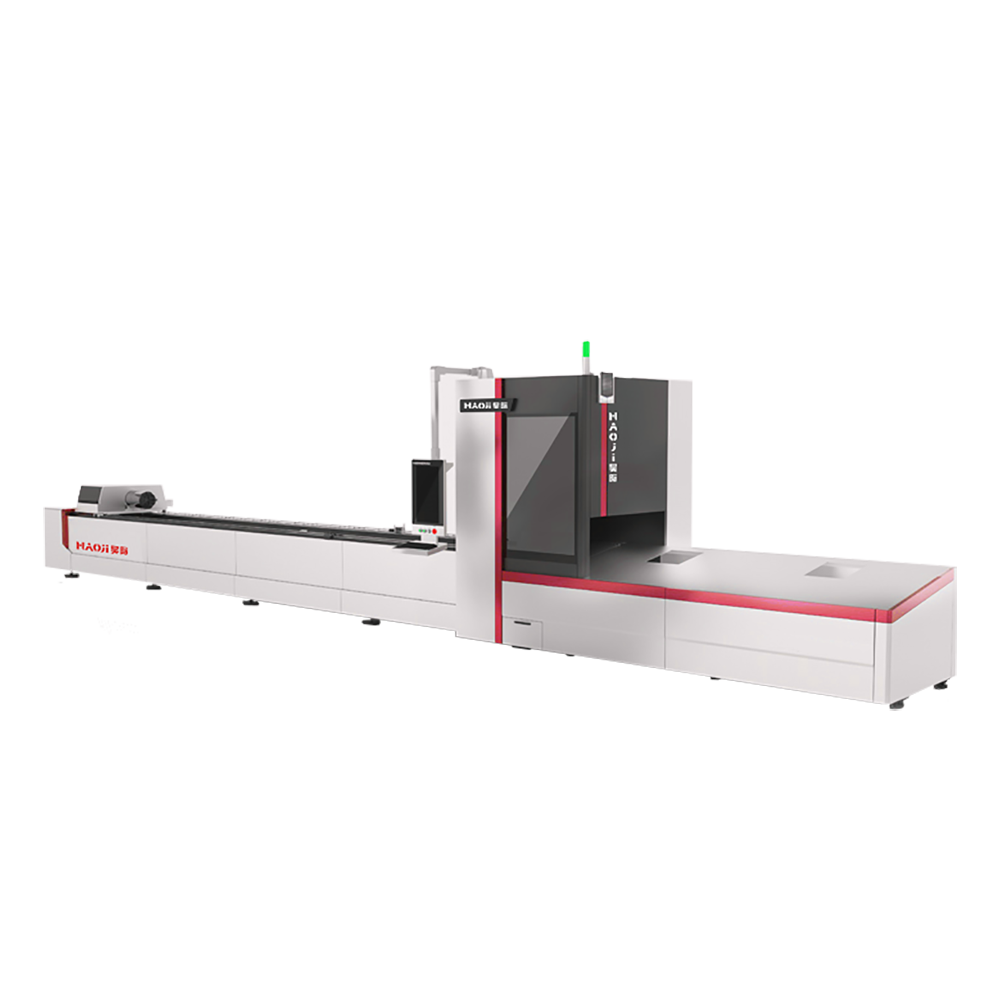

Laser power

1000~20000wMax. moving speed

140m/minRepeat positioning accuracy

0.02mmBlessing diameter

/

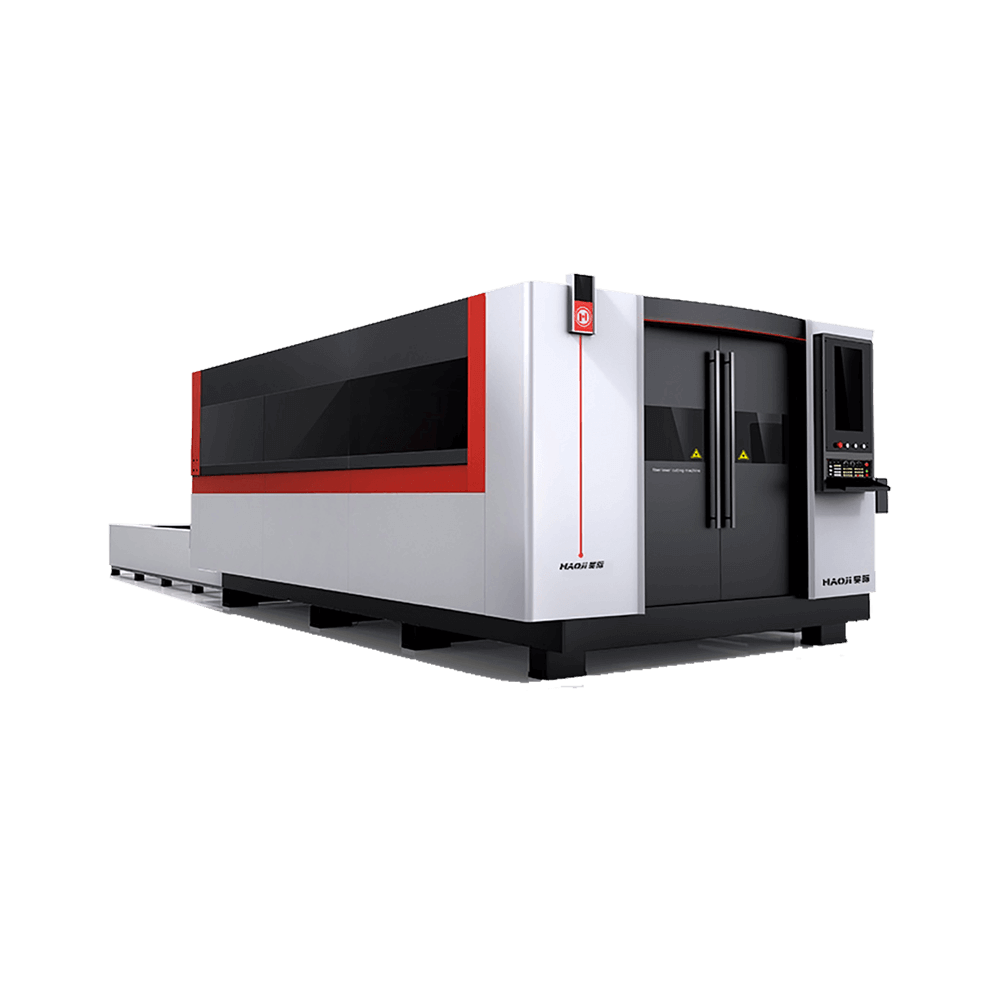

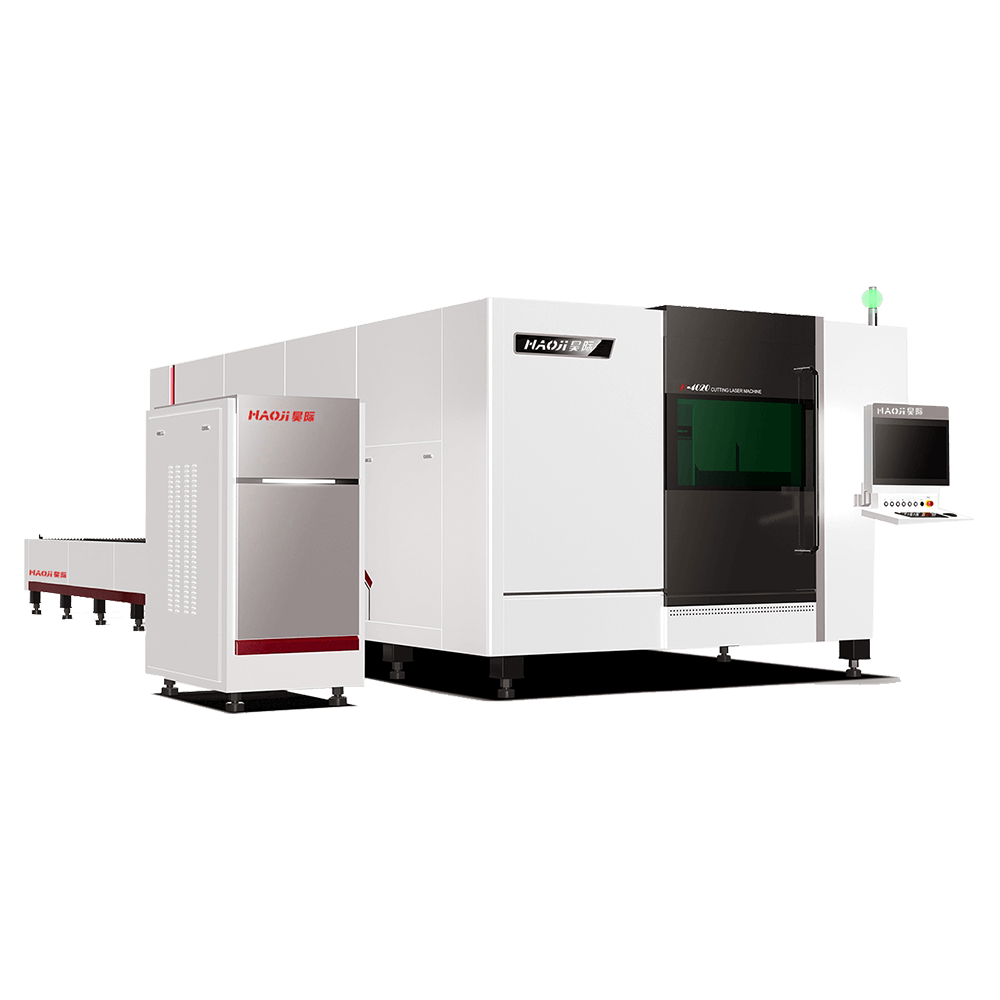

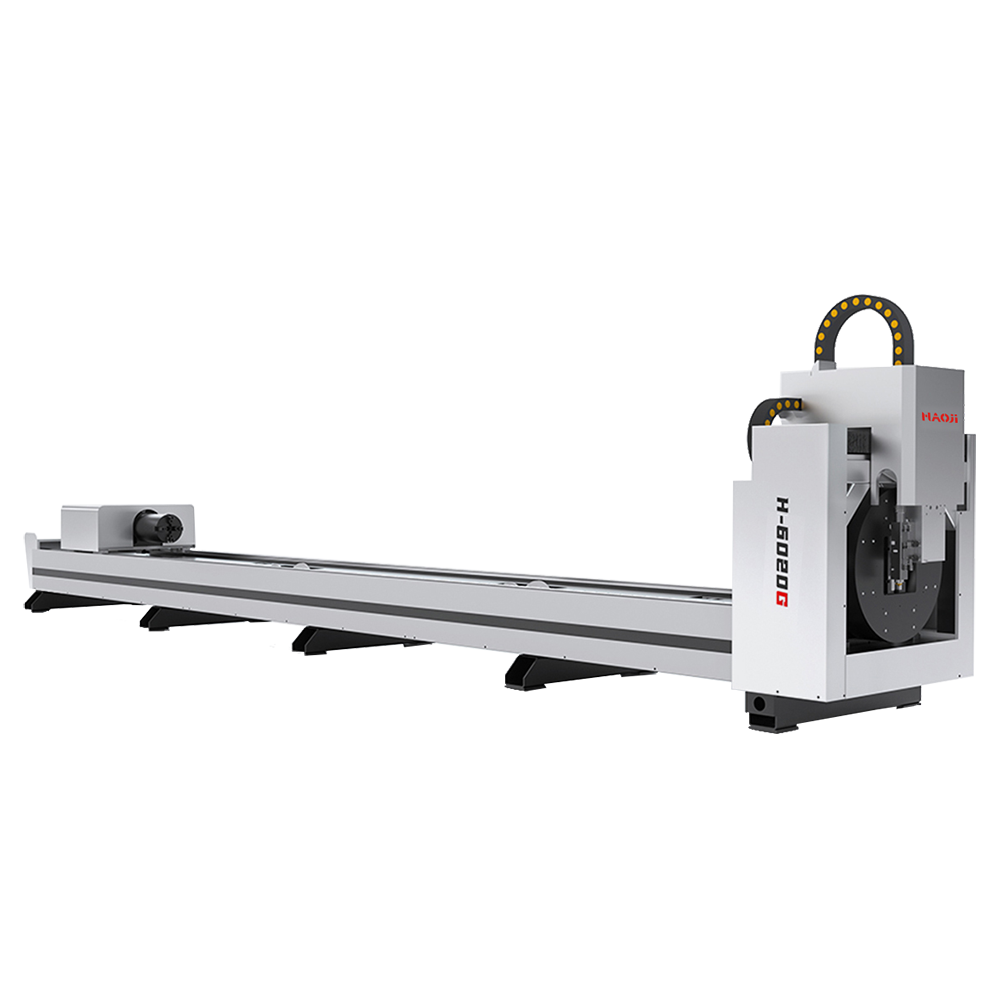

Laser power

1000~20000WMax. moving speed

140m/minRepeat positioning accuracy

0.02mmBlessing diameter

/

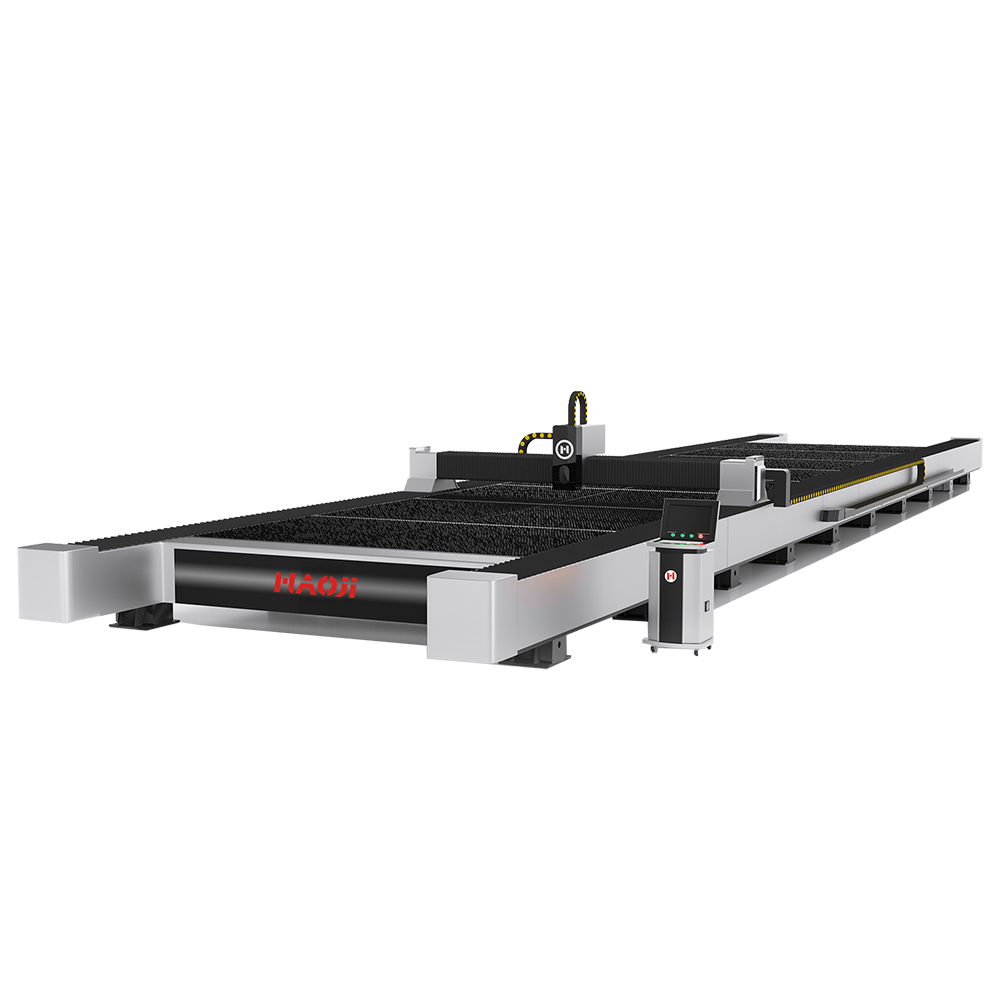

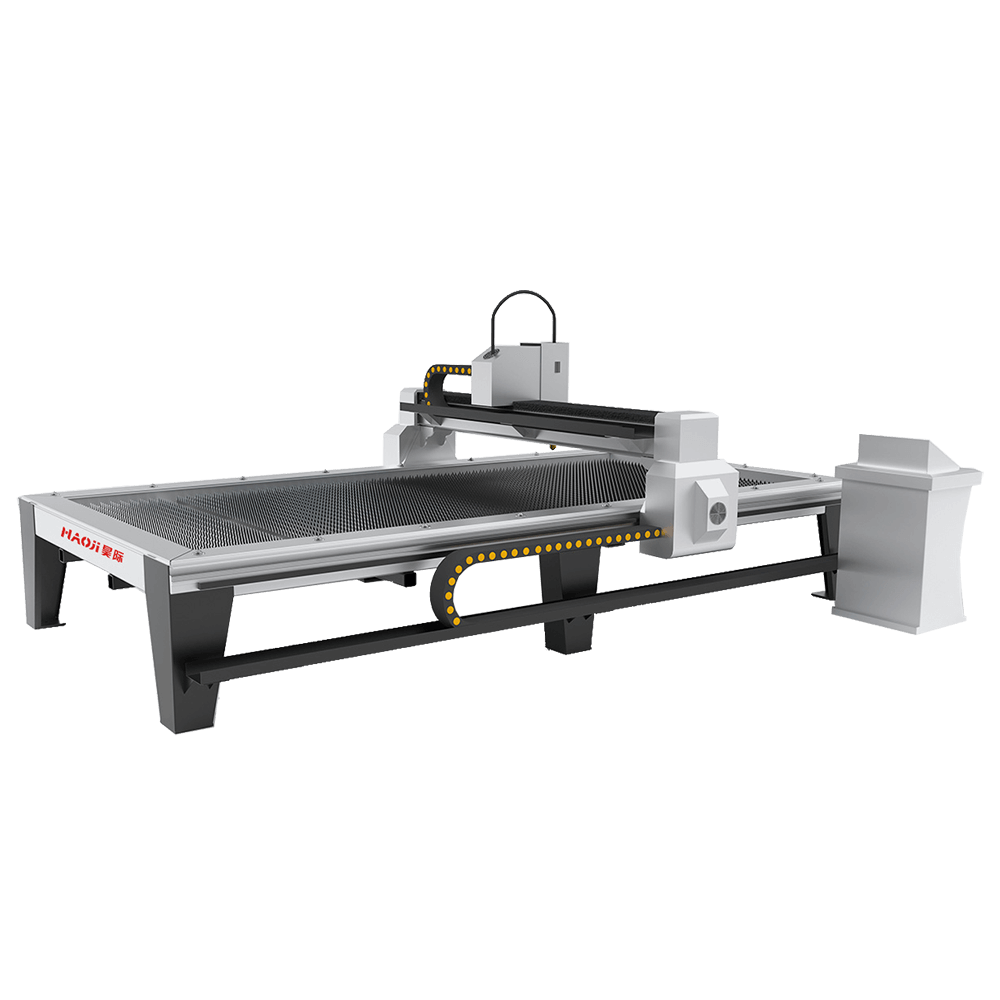

Laser power

10000-35000WMax. moving speed

200m/minRepeat positioning accuracy

0.02mmBlessing diameter

/

Laser power

1000-20000WMax. moving speed

200m/minRepeat positioning accuracy

0.02mmBlessing diameter

/

Laser power

1000-12000WMax. moving speed

140m/minRepeat positioning accuracy

0.02mmBlessing diameter

/

Laser power

3000-20000WMax. moving speed

180m/minRepeat positioning accuracy

0.02mmBlessing diameter

/

Laser power

/Max. moving speed

100m/minRepeat positioning accuracy

0.03mmBlessing diameter

/

Laser power

1000~3000wMax. moving speed

/Repeat positioning accuracy

0.02mmBlessing diameter

20-220mm

Laser power

1000~3000wMax. moving speed

/Repeat positioning accuracy

0.02mmBlessing diameter

20-220mm

Laser power

1000~3000wMax. moving speed

/Repeat positioning accuracy

0.02mmBlessing diameter

20-220mm

Laser power

1000~3000wMax. moving speed

/Repeat positioning accuracy

0.02mmBlessing diameter

20-220mm

Laser power

Max. moving speed

Repeat positioning accuracy

Blessing diameter

Laser power

Max. moving speed

Repeat positioning accuracy

Blessing diameter

Laser power

Max. moving speed

Repeat positioning accuracy

Blessing diameter

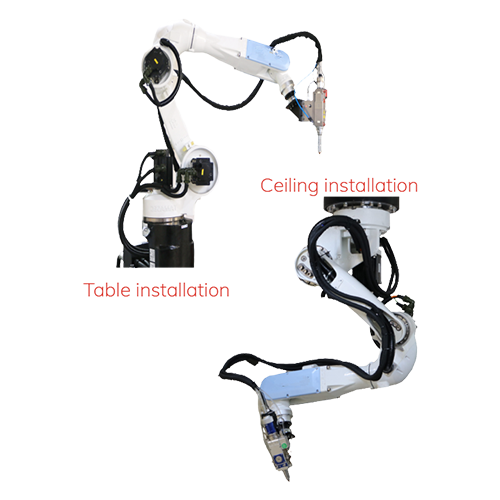

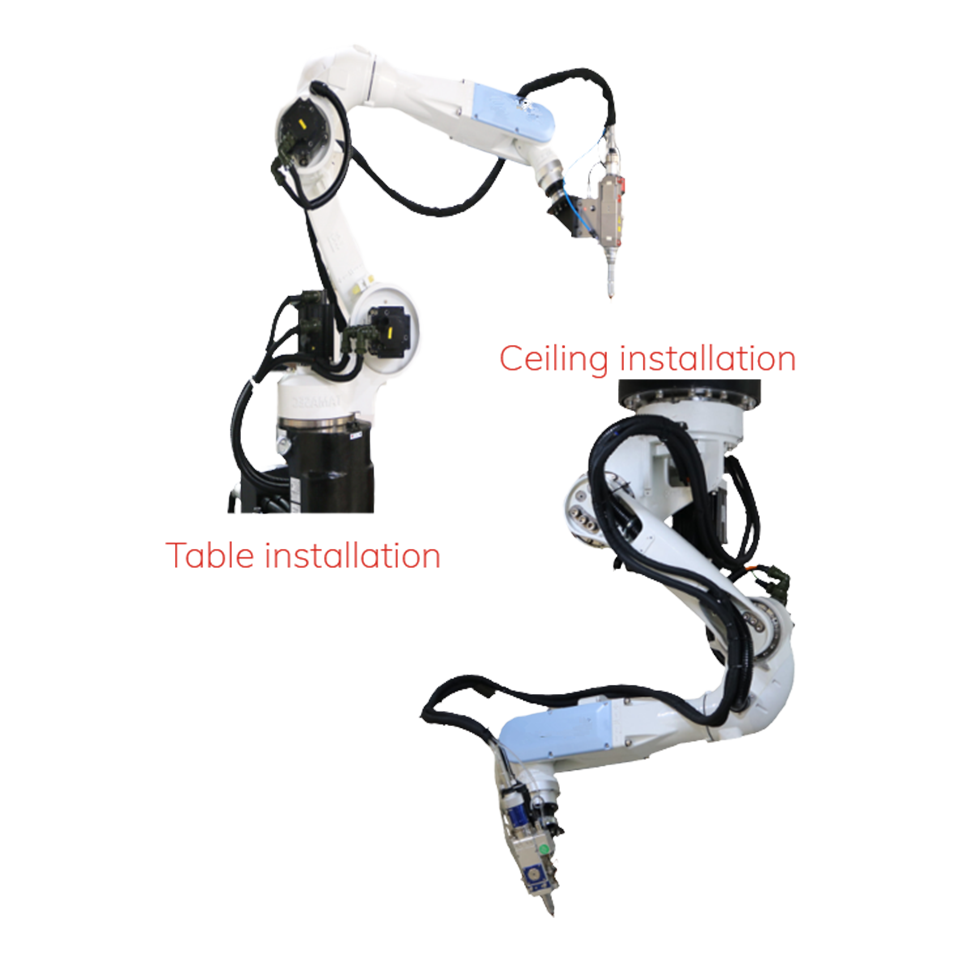

Laser power

1000W-4000WMax. moving speed

140°-600°/sRepeat positioning accuracy

±0.1mmBlessing diameter

/

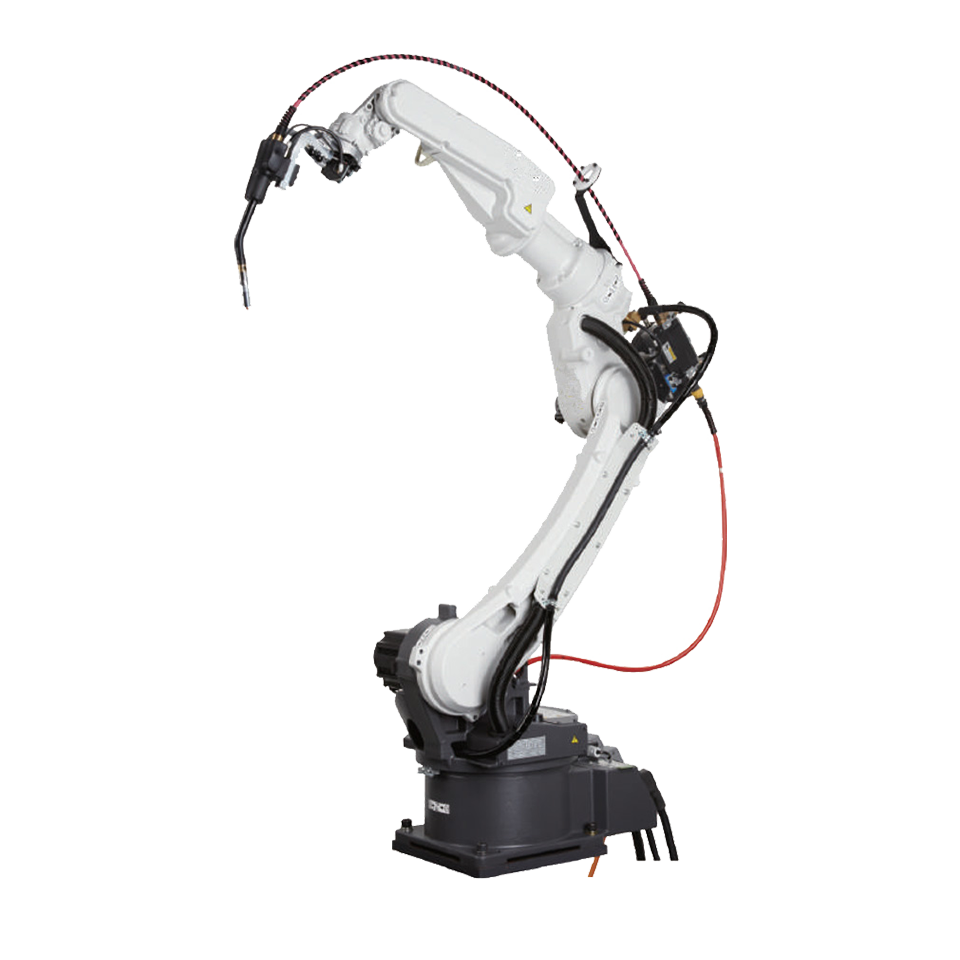

Laser power

1000-3000WMax. moving speed

140m/minRepeat positioning accuracy

0.02mmBlessing diameter

/

Laser power

1000-2000WMax. moving speed

/Repeat positioning accuracy

/Blessing diameter

/

Laser power

/Max. moving speed

/Repeat positioning accuracy

/Blessing diameter

/

Laser power

Max. moving speed

Repeat positioning accuracy

Blessing diameter

Laser power

Max. moving speed

Repeat positioning accuracy

Blessing diameter

Laser power

Max. moving speed

Repeat positioning accuracy

Blessing diameter

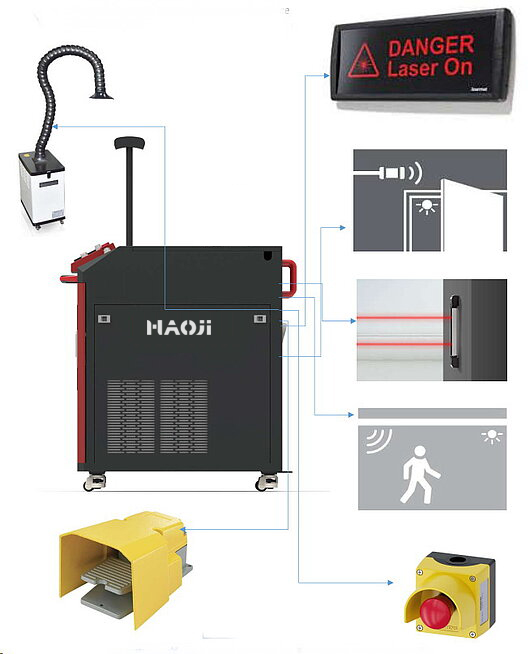

TIME:03-27 2022

What is the principle of fiber laser welding machine?

The fiber laser welding machine is to couple the laser output from the laser into the optical fiber for transmission, and then focus it on the workpiece through the laser output.

1. The fiber laser welding machine can output multiple optical fibers, which can realize energy splitting, and evenly distribute the laser energy output by the laser to each output fiber; it can also realize time splitting, and output the laser energy to each optical fiber in sequence at different time intervals. , to achieve laser welding processing at different stations at different times. Welding processing saves equipment costs for customers.

2. The laser of the fiber laser welding machine is transmitted in the form of total reflection in the fiber. During the transmission process, the fiber will homogenize the uneven position in the light spot, and the light spot formed at the output end of the fiber is a relatively uniform light spot. spot.

3. The laser has a thermal lens effect, which will change the beam diffusion angle of the laser output. If the hard optical path is used to output the laser, the focal length of the laser will change. To reduce this change, the hard optical path output is generally expanded and then focused; but If an optical fiber is used for output, the divergence angle of the laser depends on the numerical aperture NA of the optical fiber (the dispersion and its loss are relatively small, and are not considered for the time being), and the focus of the laser output is constant.

4. The optical fiber transmission laser welding machine can output the laser to the place that needs to be welded, and cooperate with the manipulator to realize the laser welding processing of continuous complex spatial curves to meet the needs of customers.

5. The energy feedback of the fiber laser welding machine is to take a part of the laser, compare the difference between the output energy before and after, and control the laser in a closed-loop to stabilize the laser output. The energy feedback is a dynamic closed-loop control, which can make the laser output not affected by the aging of the xenon lamp. When the energy of the xenon lamp is insufficient, it will automatically increase the output power of the power supply to maintain the stability of the laser; if the xenon lamp is attenuated and cannot be used, it will automatically prompt the customer to replace the xenon lamp .

The fiber laser welding machine, whether it is a mirror frame or a condenser cavity, is generally used for several months. When the equipment is continuously used and vibrated, the alignment of the lens will decrease. If the energy output is weakened, the optical path should be slightly adjusted to restore the energy output. . Energy feedback can improve the output of the laser to a certain extent. When the alignment of the lens decreases, it will automatically replenish the energy.